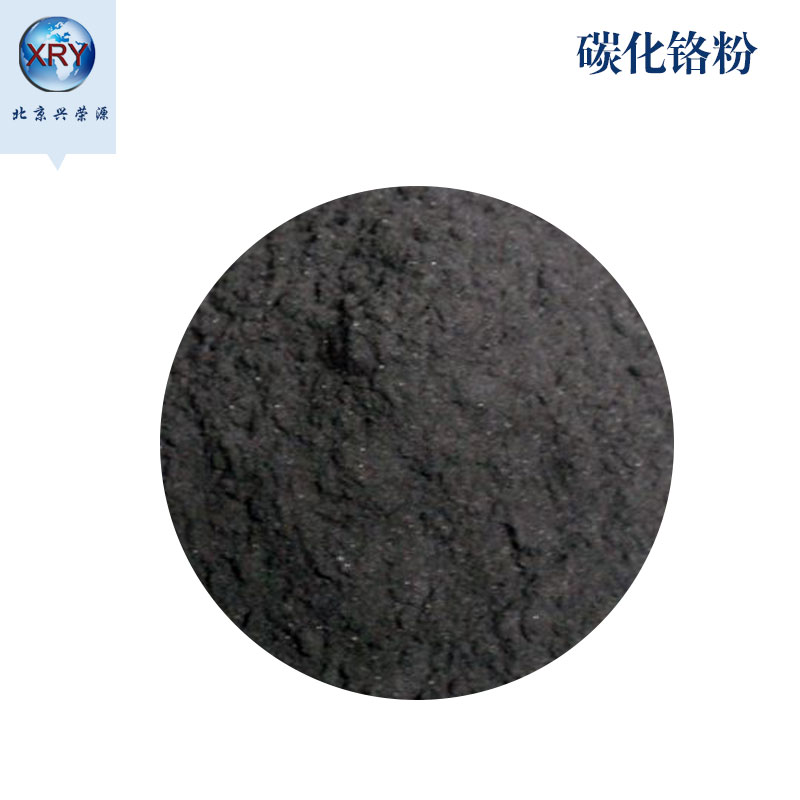

Chromium carbide powder

product details

(1) Product features: high melting point inorganic material with good wear resistance, corrosion resistance and oxidation resistance.

(2) Product application: chromium carbide, usually used as grain refiner of cemented carbide, flux cored wire addition, hard surface material or plasma spraying powder (nichrome carbide) or other main raw materials of hard and wear-resistant coating.

(3) Product specification: 60-200 mesh, 150 mesh, 200 mesh, 300 mesh ultrafine powder: 3.2-2.6 μ m, 1.5 μ M

(a) Commonly used grain size of wear-resistant welding material industry: 60-200 mesh, or 80-250 mesh; (b) commonly used grain size of plasma spraying industry; 150-325 mesh, 200-300 mesh, 45-15 μ m or according to customer requirements. (c) 3.2-2.6 μ m 1.5 μ m is used in cemented carbide or powder metallurgy additive industry.

(4) Chemical composition and physical index (as shown below)

(5) Product executive standard: YS / T 422.3-2000

|

Chemical composition and product specification |

||||||||

|

Brand name |

Main chemical composition(%) |

The following impurities are not more than(%) |

||||||

|

Cr3C2 |

Cr |

C |

游离碳 |

Fe |

Si |

Al |

S |

P |

|

88-90 |

9-11 |

0.1% |

0.5 |

0.15 |

0.15 |

0.03 |

0.02 |

|

|

Cr3C2 |

78-80 |

18-21 |

0.2% |

0.8 |

0.3 |

0.3 |

0.3 |

0.02 |

|

Particle size specification: 60-200 mesh, 150 mesh, 200 mesh, 300 mesh ultrafine powder: 3.2-2.6 μ m, 1.5 μ M Common granularity in different industries (1) Common grain size of wear-resistant welding material industry: 60-200 mesh, or 80-250 mesh (2) Particle size commonly used in plasma spraying industry: 150-325 mesh, 200-300 mesh, 45-15 μ m or as required by customers. (3) 3.2-2.6 μ m 1.5 μ m for cemented carbide or powder metallurgy additive industry |

||||||||